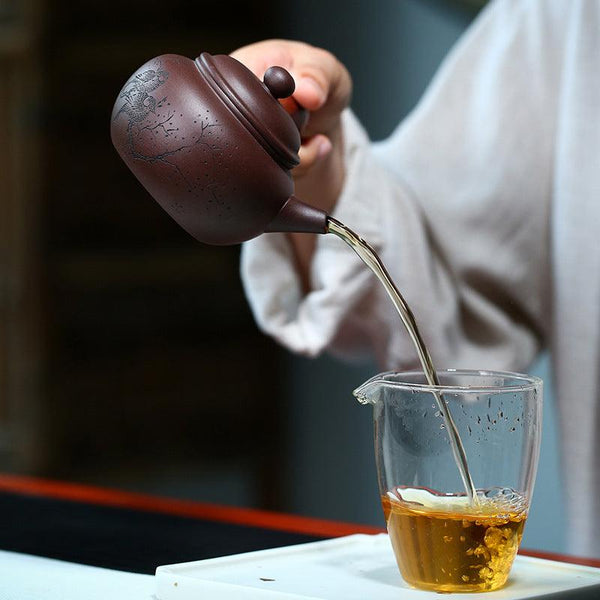

Yixing Zisha, often referred to as the "purple sand" pottery of China, holds a revered place in the world of ceramics, particularly in the crafting of teapots. Originating from the Yixing region in Jiangsu province, this unique ceramic style has been celebrated for over a thousand years, and it has become synonymous with Chinese tea culture. The name "Zisha" literally translates to "purple sand," which refers to the distinctive clay from which these teapots are made. Unlike other ceramic traditions, Yixing teapots are known for their ability to enhance the flavor of tea, thanks to the porous nature of the clay, which allows for optimal brewing conditions. Over time, Yixing Zisha pottery has evolved, merging traditional craftsmanship with modern techniques to create functional art pieces that continue to be valued by collectors and tea enthusiasts around the world. This article will explore the modern methods used in Yixing Zisha processing, compare them with traditional practices, and look at the future of this iconic craft.

Key Steps in Modern Zisha Processing

The processing of Yixing Zisha pottery today follows a refined set of steps, combining age-old techniques with contemporary innovation. The process begins with the collection of the Zisha clay, which is mined from the hills surrounding Yixing. The clay is composed of a unique mix of minerals, such as kaolin, quartz, and iron oxide, which give the pottery its characteristic colors and textures. Modern potters have access to both traditional clay and newer blends that allow for greater consistency and malleability.

Once the clay is sourced, it is prepared by grinding it into a fine powder and mixing it with water to create a malleable paste. This paste is left to rest for several hours, allowing the moisture content to balance and ensuring the clay achieves the right texture for molding. In modern production, some potters use specialized machines to assist with this step, making it less labor-intensive. The pottery is then molded. While traditional methods involve hand-building the teapot using techniques like coiling or molding by hand, modern potters often incorporate molds and automated equipment to achieve more precise shapes. This approach helps maintain consistency, especially in mass production, while still preserving the artistic quality. After shaping, the teapot undergoes its first firing, or "bisque firing," at temperatures between 800°C and 1000°C. High-tech kilns are used in modern Zisha processing, offering precise control over temperature and atmosphere, ensuring the desired color, texture, and functionality.

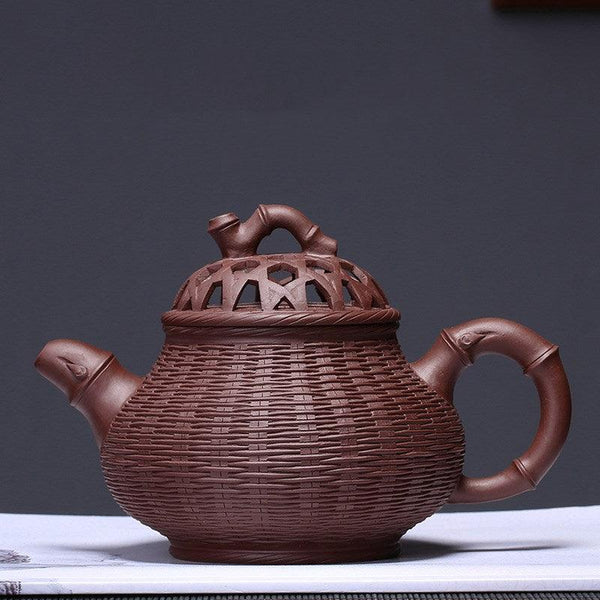

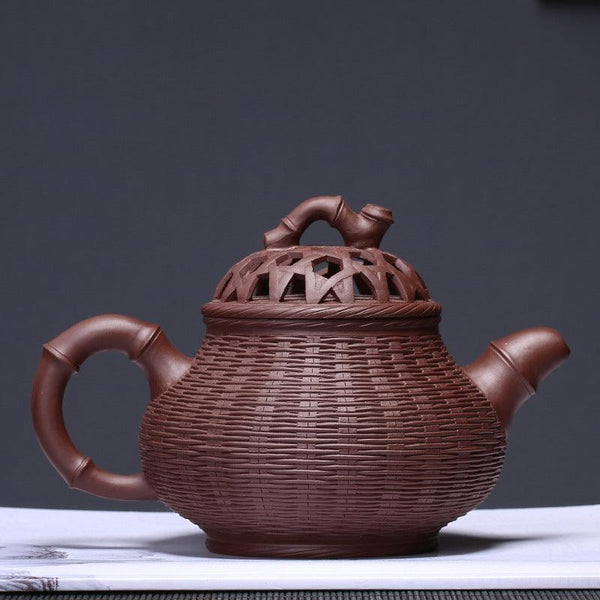

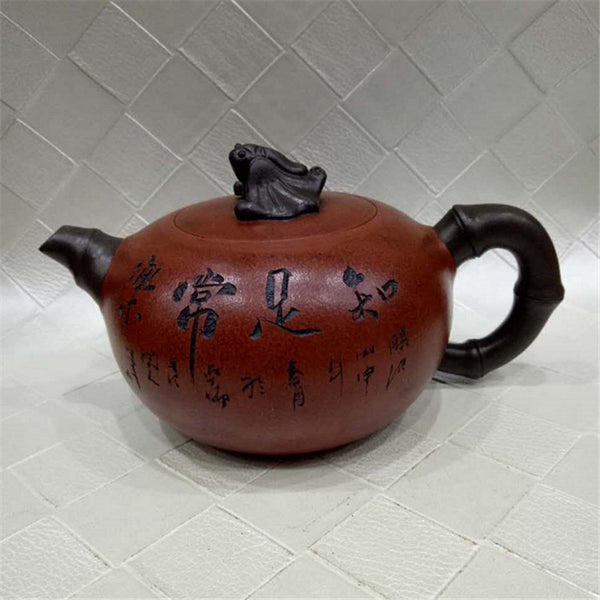

The next step in Zisha pottery is decoration, where modern artists use techniques like engraving, carving, and adding colored slips or glazes to enhance the teapots' appearance. Unlike traditional methods, where designs were applied by hand, some contemporary potters employ computer-controlled machines for precise carving and engraving. Despite this, handcrafting remains crucial for details like spouts, handles, and lids, preserving each piece's uniqueness. The teapot then undergoes a second firing at 1100°C to 1200°C, sealing the pottery and enhancing its durability. Modern kilns offer advanced heat distribution, preventing cracks and ensuring the final product meets high-quality standards.

Comparison with Traditional Methods

Modern Zisha pottery techniques have brought advancements in efficiency and precision, yet traditional methods remain deeply valued. Historically, Yixing Zisha pottery was crafted manually, with potters relying on handcrafting and traditional tools passed down through generations. The main difference between traditional and modern methods is the level of mechanization. Traditional potters shaped and fired pottery by hand, resulting in unique, one-of-a-kind pieces with distinct textures and colors. In contrast, modern methods use machines for tasks like mixing clay and molding, ensuring consistency, but some argue this detracts from the personal connection and artistry of the craft. Some potters blend both approaches to preserve tradition while embracing innovation.

Future of Yixing Zisha

The future of Yixing Zisha pottery lies in the ability to preserve its cultural significance while adapting to the changing needs of the global market. As global interest in Chinese tea culture continues to grow, so too does the demand for Yixing Zisha teapots. However, the modern potter faces the challenge of balancing mass production with artistic integrity. The use of automation, such as 3D printing and advanced kiln technologies, may help ensure the continued accessibility and affordability of Yixing teapots without sacrificing quality.

At the same time, there is a growing emphasis on sustainable practices in pottery making. Many modern potters are exploring ways to minimize waste and reduce their environmental impact, such as using eco-friendly materials and energy-efficient kilns. These innovations could ensure that Yixing Zisha pottery remains relevant and environmentally conscious in the coming decades.

Conclusion

Yixing Zisha pottery is a perfect blend of tradition and modernity. The modern methods of processing Zisha clay allow for greater efficiency and precision, while still preserving the artistry that makes each teapot a work of functional art. As Yixing pottery continues to evolve, it is important to remember the deep cultural and historical significance that has been passed down through generations. The future of Yixing Zisha is bright, with exciting developments on the horizon, ensuring that this treasured craft will remain a cornerstone of Chinese tea culture for generations to come.